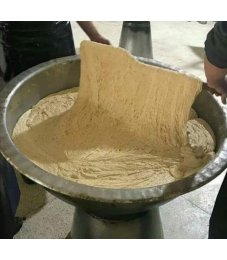

HALWA SUGAR COOKER MACHINE

HALWA SUGAR COOKER MACHINE

Professional Halva Production Solutions with Foodmac Halva Machine

Foodmac provides significant advantages to businesses in tahini halva production with its high-performance and innovative food processing technologies. Specializing in halva machines, tahini machines, halva paste making machines, and complete production systems, Foodmac combines quality, hygiene, and efficiency to deliver fully integrated solutions for industrial producers.

Below are the standout features of Foodmac’s tahini halva machines and the reasons why the brand is a preferred choice in the sector.

1. Efficient Halva Production with High Capacity

The Foodmac halva machine, with a production range from 100 kg to 300 kg per hour, is an ideal choice for businesses looking to establish a large-scale halva production facility. Thanks to its high-capacity performance, it helps you scale up your daily production and easily reach your operational targets. It integrates seamlessly with tahini grinders and other preprocessing units to accelerate overall production workflows.

2. Advanced Technology, Hygiene, and Durability

Constructed from 304-grade stainless steel, Foodmac machines provide top-tier hygiene and extended durability. Equipped with advanced motor systems, the halva paste making machine and other tahini halva production lines ensure optimal performance even under intensive production conditions.

3. Energy Efficiency and Low Operating Costs

Developed with an eco-conscious approach, Foodmac machines are designed to consume minimal energy while delivering maximum output. This not only reduces operational costs but also supports sustainable production—a critical advantage for facilities involved in tahini manufacturing and halva production.

4. User-Friendly Design and Flexible Adjustment Options

The Foodmac tahini halva machine features intuitive control panels, variable speed settings, and a custom paddle design that allows operators to easily adjust the consistency of tahini during production. This helps maintain your quality standards while saving time and labor.

5. High-Quality Standards and Long-Term Solutions

Foodmac is committed to manufacturing food machinery with uncompromising quality. Using long-lasting components and precision engineering, its machines—whether for halva or tahini production—are built to run smoothly for years without interruptions, ensuring a long-term return on investment.

6. Easy Maintenance and Strong Technical Support

Beyond production, Foodmac stays by your side. All machines are designed for easy maintenance and are backed by regular servicing options. In case of malfunctions or spare part needs, the Foodmac team delivers fast and effective solutions, minimizing downtime and keeping your production line running smoothly.

⭐ Why Choose Foodmac Halva Production Machinery?

With its wide product range—including halva machines, tahini mills, and halva paste making systems—Foodmac offers tailored solutions for small, medium, and large-scale food producers. As a locally manufactured yet globally competitive brand, Foodmac exports to many countries and has established a strong presence worldwide.

???? Ready to Build a Professional Halva Production Facility?

If you’re looking to build a hygienic, high-quality halva production system, Foodmac is the right choice. Get in touch with us today for detailed information, pricing, or customized machine offers.

Foodmac: Powering Your Halva Production with Technology.

Boost Your Halva Production with Foodmac’s Professional Halva Machines

At Foodmac, we empower food manufacturers with high-performance and innovative food processing machines, especially in the field of tahini halva production. Our advanced systems — including the halva machine, tahini machine, halva paste mixing machine, and fully integrated production lines — are designed to deliver maximum efficiency, hygiene, and durability for industrial-scale operations.

Here’s why Foodmac is a leading choice for businesses aiming to establish or upgrade their halva production facility:

1. ???? High Capacity for Efficient Halva Production

Foodmac halva machines offer production capacities ranging from 100 kg to 300 kg per hour, making them ideal for high-volume operations. These machines enable you to meet daily production goals with ease. Seamlessly integrated with tahini grinders and other preprocessing equipment, they accelerate production processes and minimize bottlenecks.

2. ????️ Advanced Technology, Hygiene & Durability Combined

Built with 304-grade stainless steel, Foodmac machines meet strict hygiene standards and ensure long-lasting performance. From the halva paste mixer to complete production lines, every unit is engineered with powerful motors and smart components to withstand continuous operation in demanding production environments.

3. ???? Energy-Efficient Design with Low Operating Costs

Sustainability is at the core of our design philosophy. Foodmac machines are optimized for low energy consumption, helping you reduce operating costs while maintaining top-tier productivity. This energy efficiency is particularly valuable for facilities engaged in tahini and halva production.

4. ????️ User-Friendly Operation with Flexible Adjustments

Our machines feature intuitive digital control panels, variable speed systems, and precision mixing mechanisms that allow operators to easily adjust the texture and consistency of tahini during halva production. This results in consistent product quality and saves time during every production cycle.

5. ????️ Built to Last: Long-Term Investment Value

Foodmac machines are manufactured to meet the highest industry standards. Using premium materials and robust mechanical systems, each machine is designed for years of uninterrupted use. Whether it’s a tahini machine or a full-scale halva production line, Foodmac guarantees reliability and longevity.

6. ???? Simple Maintenance & Responsive After-Sales Support

Foodmac offers more than just machinery — we deliver peace of mind. Our machines are easy to clean and maintain, and our technical support team is always ready to assist with spare parts, servicing, and troubleshooting. This ensures that your production runs smoothly with minimal downtime.

???? Why Choose Foodmac?

From small workshops to large-scale food manufacturers, Foodmac provides tailored halva production solutions to meet every need. As a locally engineered brand with a global export reach, we are trusted by companies across Europe, the Middle East, and beyond.

If you're looking to establish a professional halva production facility, ensure hygienic, consistent, and profitable output, and scale your operations, Foodmac is your ideal partner.

???? Contact us now for a customized quote, product demo, or consultation.

Foodmac – Powering Your Halva Production with Innovation.

Site Tasarım: GüneşSoft