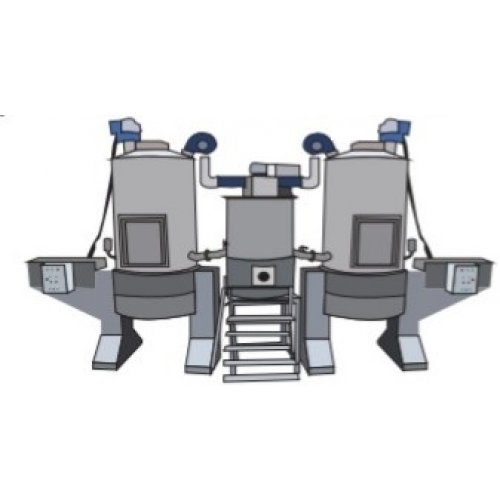

HALWA SUGAR COOKER MACHINE (200 KG)

HALWA SUGAR COOKER MACHINE (200 KG)

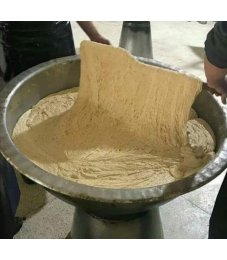

Foodmac Helva Pulling Machine: Optimized for High-Efficiency Helva Production

Foodmac provides tailored solutions for the helva manufacturing industry with machines that combine efficiency, hygiene, and quality in one system. The helva pulling machine, in particular, is an essential component for businesses engaged in tahini production and helva processing.

This advanced system ensures the perfect consistency of the sugar and çöven extract mixture before blending with tahini during production. Engineered by Foodmac, the machine offers high capacity, energy efficiency, and long-term durability—making it ideal for modern helva manufacturing plants.

⚙️ Technical Specifications & Production Capacity

???? Heating Options:

Recommended use with LPG (propane, butane, or blends). The system also supports alternative fuels such as natural gas, fuel oil, diesel, or wood.

???? Industrial LPG Burner:

Efficiently mounted beneath the sugar beating kettle to ensure fast and uniform heating.

⚖️ Batch Capacity:

The pulling kettle can process between 200 kg and 250 kg of sugar-çöven mixture. Each batch takes approximately 45 minutes to prepare.

???? Final Helva Output:

Once blended with tahini, the cooked mixture yields 400 kg to 500 kg of tahini helva. Larger capacity machines are available upon request.

⚡ Motor Power Ratings:

-

Sugar Beating Kettle: 4 kW

-

Sugar Boiling Kettle: 2.2 kW

-

Fan Motor: 0.37 kW

???? Food-Grade Materials:

All food-contact surfaces are made from 304-grade stainless steel, ensuring food safety and easy cleaning.

✅ Why Choose Foodmac?

Foodmac helva machines ensure superior performance during the production process and seamlessly integrate with other equipment such as tahini mills and processing lines. Thanks to their durable design and energy-saving features, they help businesses increase production efficiency and profitability.

Perfect for medium and large-scale helva production facilities, Foodmac’s helva pulling machines modernize your production line while raising hygiene and quality standards.

???? Contact Us Today for More Information & a Custom Quote

Foodmac empowers your helva production—professionally and reliably.

Site Tasarım: GüneşSoft